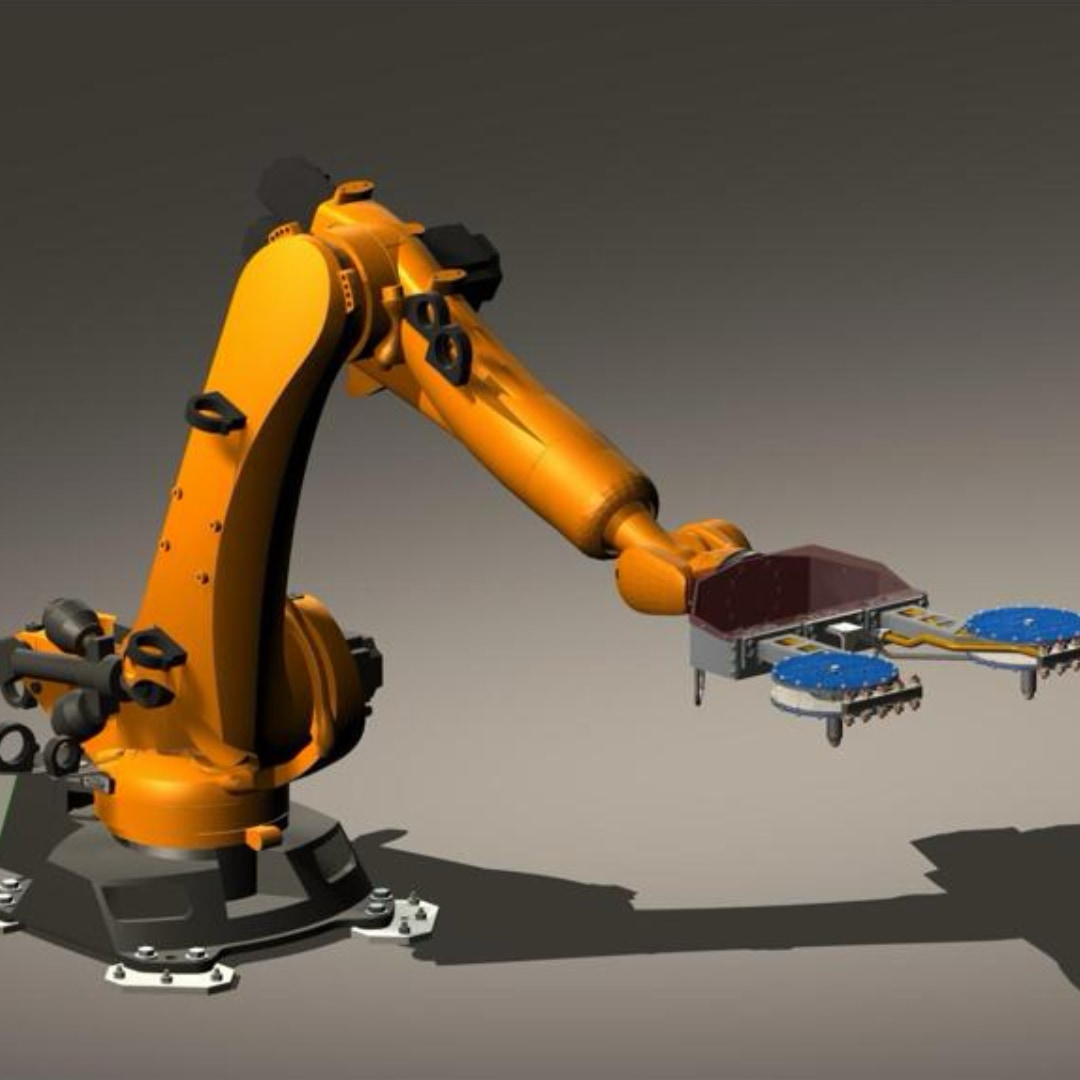

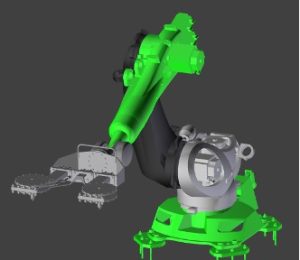

Maximum Flexibility And Unique Operation Concept

Jerko spray robots provide a maximum degree of flexibility. The free configuration of movements combined with a proportional volume control during the movement ensures an efficient spraying process.

Even points that are difficult to access can be precisely sprayed when using the robot and our unique spray heads.

The robot is equipped with up-to-date communication functions and all safety features, allowing for perfect integration into existing forging lines.

Are you skeptical about the programming effort?

The user interface developed by Jerko allows you to learn the programming steps within a few hours. The sequence of motions can be programmed using simple touch buttons and inputting the rates. The intelligent Jerko control takes care of the rest.

Extensive and cost-intensive training and programming efforts are now a thing of the past!

From the smallest to the largest robot — do not hesitate to contact us for advice and support to select the optimum spray tool for your needs.

Plate Spray Head

Combined Spray Head

Jerko is the No. 1 in high-performance spray and coating systems for forging industry.

Our mission: Maximize uptime. Minimize costs.

Powered by PBMSys