Precision. Speed. Reliability.

Jerko JB Series – The only real solution for demanding forging applications.

No clogging. No recalibration. No downtime.

The Jerko valves of the JB series are uncompromisingly designed for maximum system availability. While many systems suffer from wear, deposits, and clogging in daily operation, our valve consistently delivers top performance – even when handling high-viscosity lubricants, extreme heat, and heavily contaminated spray media.

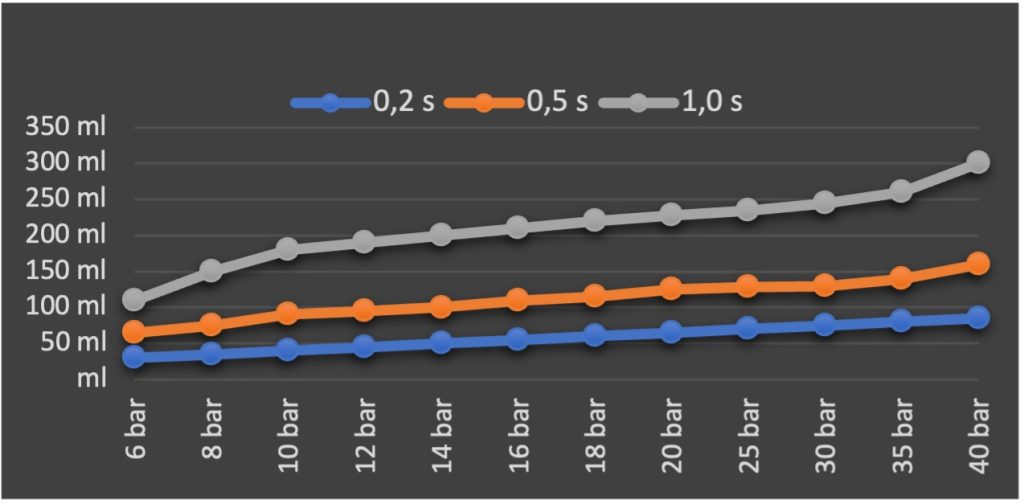

JB1401 & JB1413

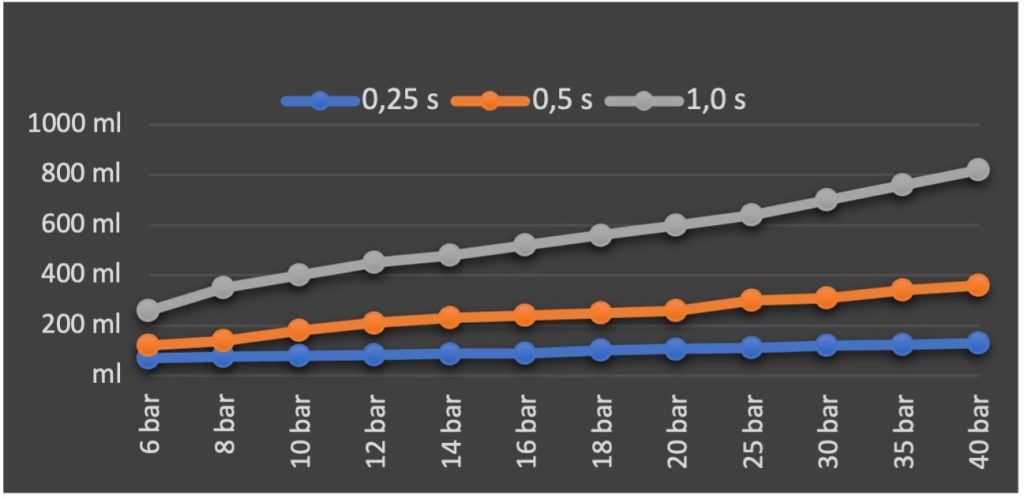

JB1412

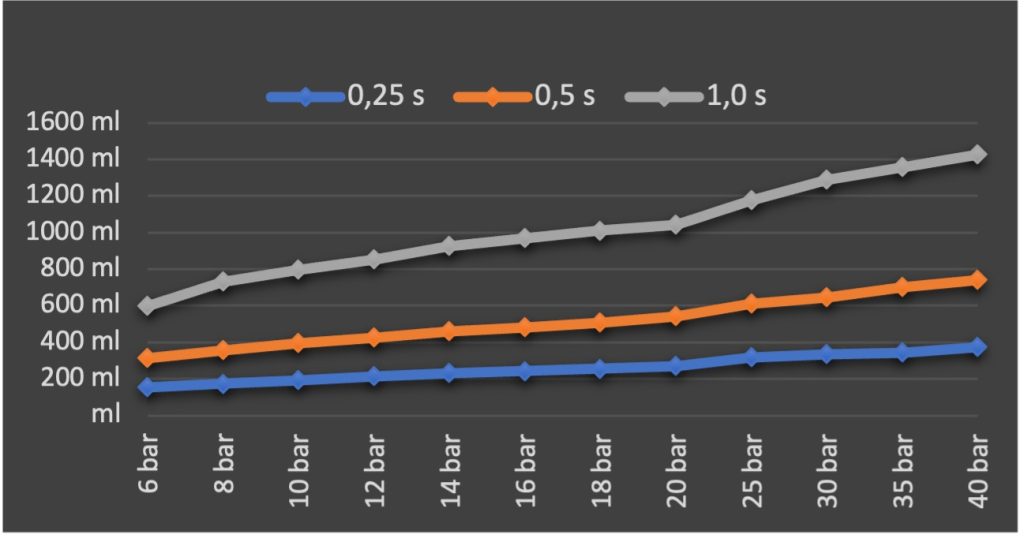

JB1430

Jerko is the No. 1 in high-performance spray and coating systems for forging industry.

Our mission: Maximize uptime. Minimize costs.

Powered by PBMSys