Unmatched Speed. Maximum Performance.

Engineered to Outlast.

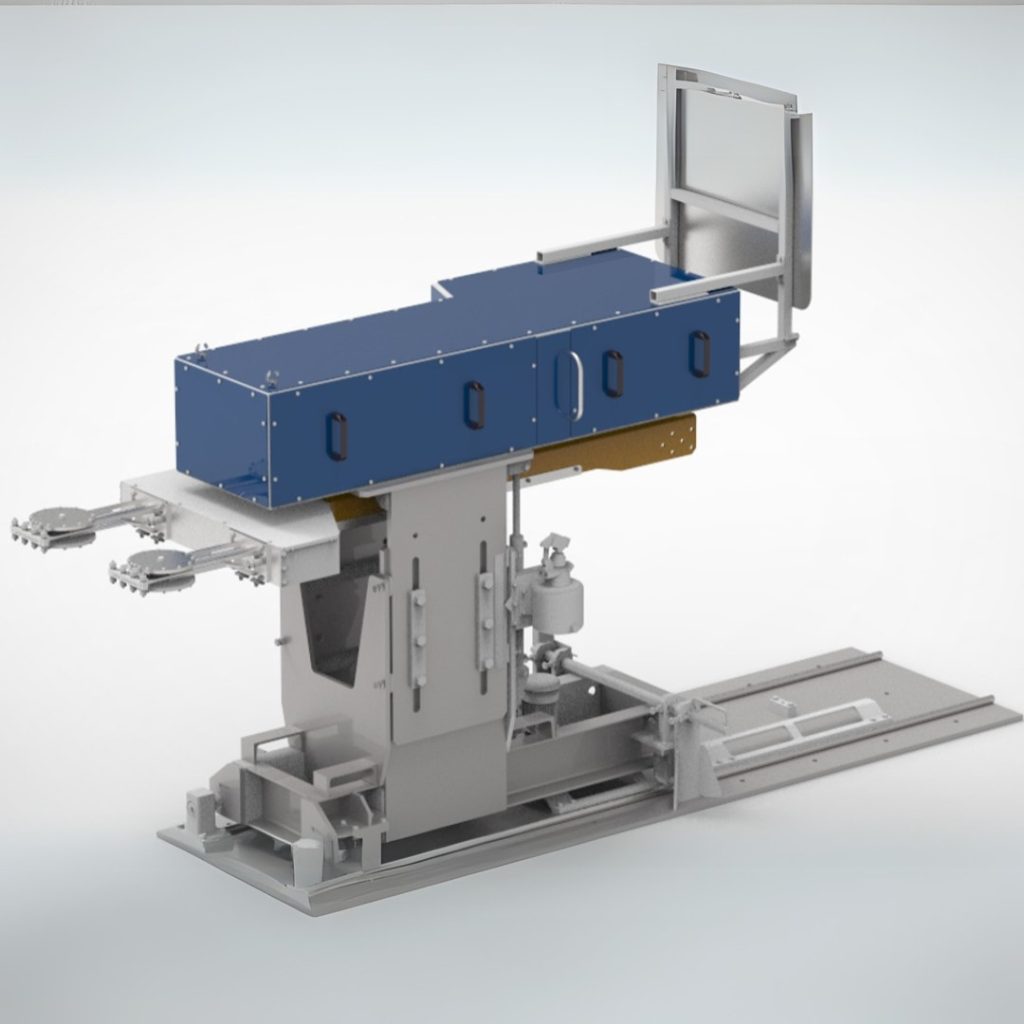

erko manipulators set a new global benchmark for forging automation. Designed for maximum uptime and engineered to withstand the harshest shop-floor conditions, they are in a league of their own.

With an enclosed drive concept, these units offer 100 % protection against dirt, debris, and temperature extremes – all while maintaining exceptional payload capabilities.

Driven by a powerful servomotor and low-maintenance toothed belt, our manipulators deliver rapid acceleration with absolute precision.

Thanks to their compact and modular design, they can be integrated into any forging line without the need for extensive adjustments or retrofits. Whether you require single-axis movement or complex multi-axis setups, Jerko manipulators adapt seamlessly to your process.

From standard applications to highly customized configurations – we provide speed, strength, and system longevity that competitors simply can’t match.

Fastest manipulator system on the market – hands down

Engineered for 24/7 uptime: Availability > 99 %

Payloads up to 300 kg – without sacrificing speed

Robust mechatronics, minimal wear, low MTTR

Flexible architecture for scalable automation

Developed to outperform – even under extreme conditions

Available standard sizes – tailored to your performance needs

BG1

Stroke: 800–1600 mm

Max. Load: 75 kg

Cycle Time (1000 mm): < 550 ms

BG2

Stroke: 800–1600 mm

Max. Load: 200 kg

Cycle Time (1000 mm): 550 ms

BG3

Stroke: 1200–2400 mm

Max. Load: 300 kg

Double Acting BG1 – BG3

All manipulators available as double-acting version

Jerko is the No. 1 in high-performance spray and coating systems for forging industry.

Our mission: Maximize uptime. Minimize costs.

Powered by PBMSys