Save the Date: IFC Frankfurt

5–10 October 2025

From 5–10 October 2025, the forging industry will gather in Frankfurt for the International Forging Congress (IFC) – one of the most important global events for our sector.

We are proud to announce that Jerko will be exhibiting together with our partner GEVA at booths 33 & 34.

🔹 This is your opportunity to meet the leading experts in spray technology for forging – face to face.

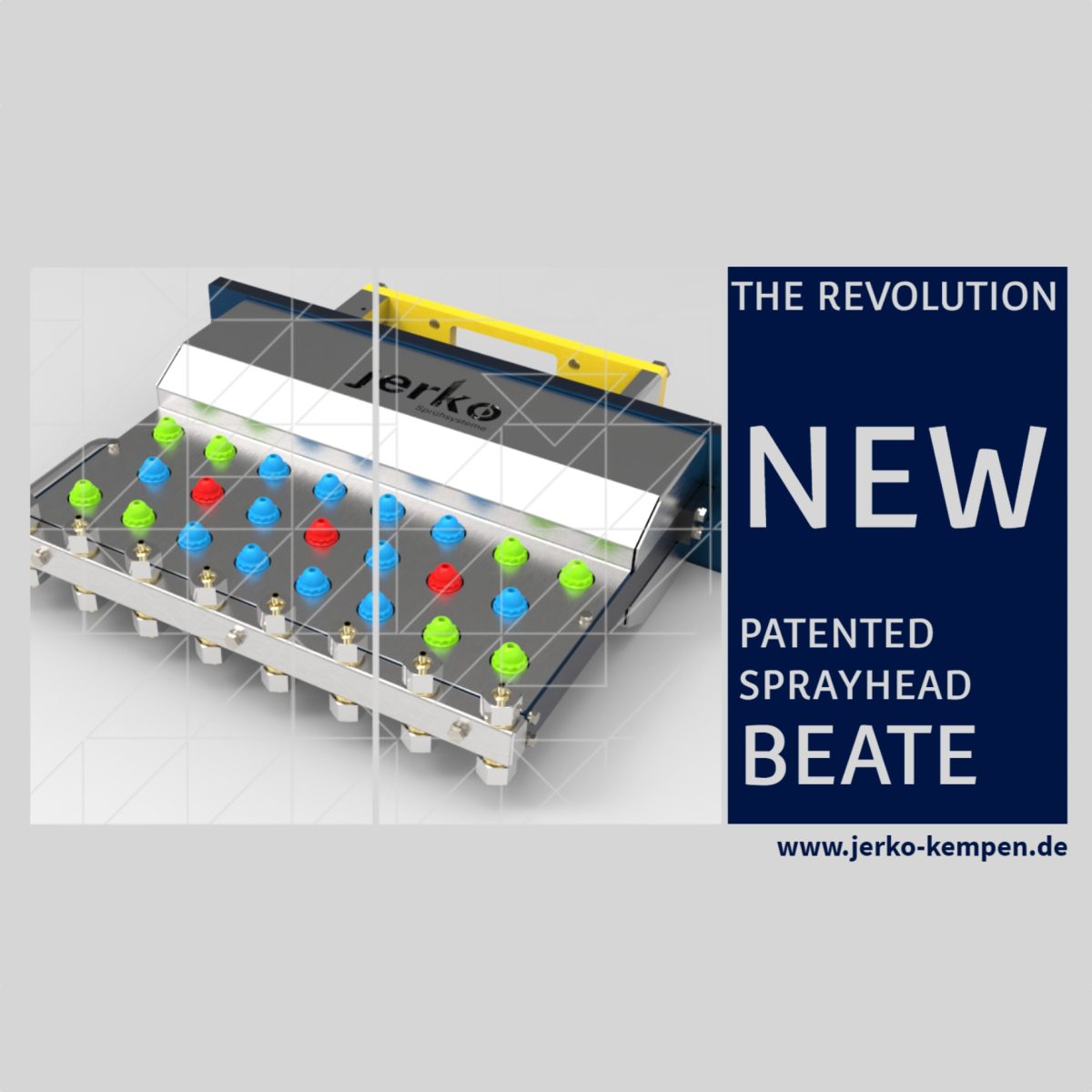

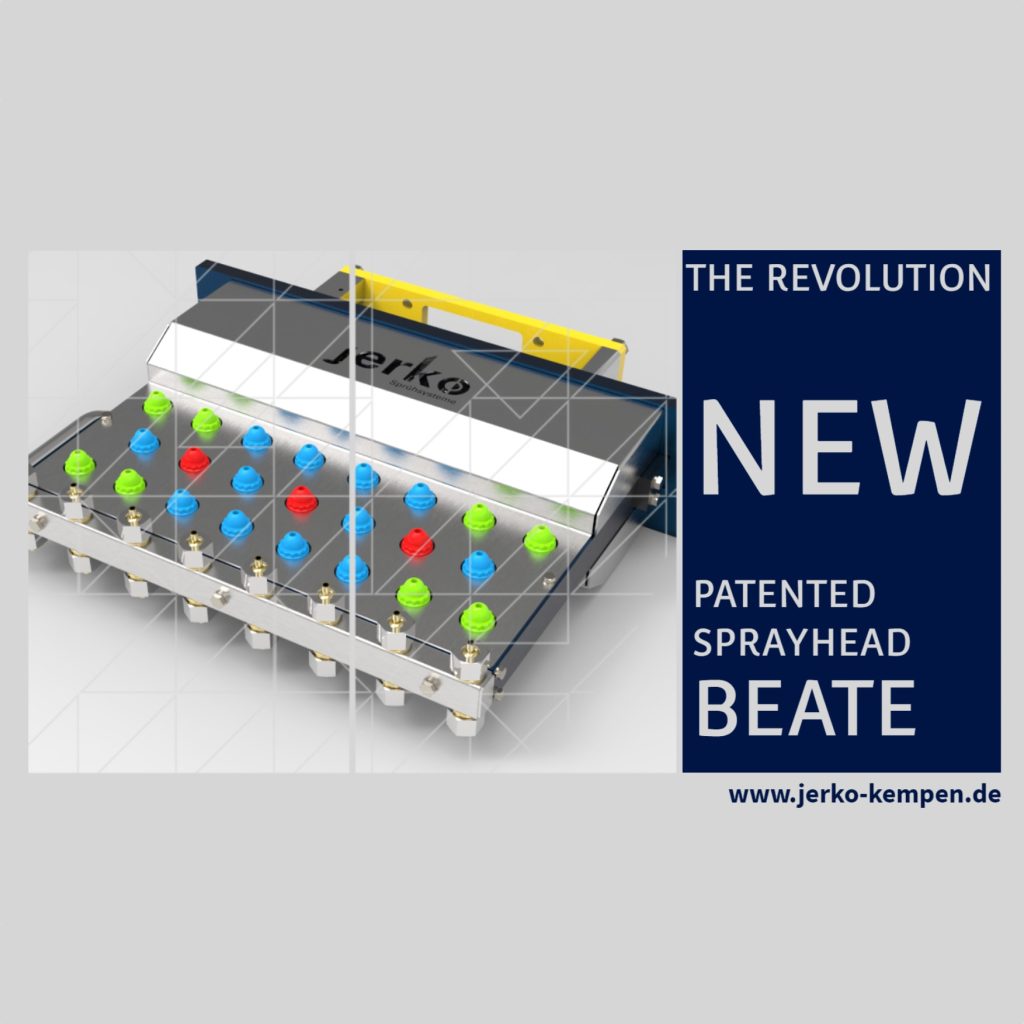

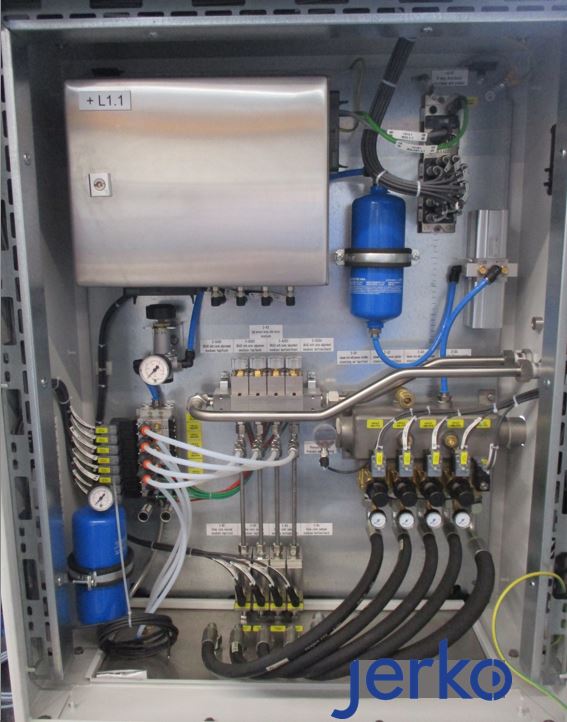

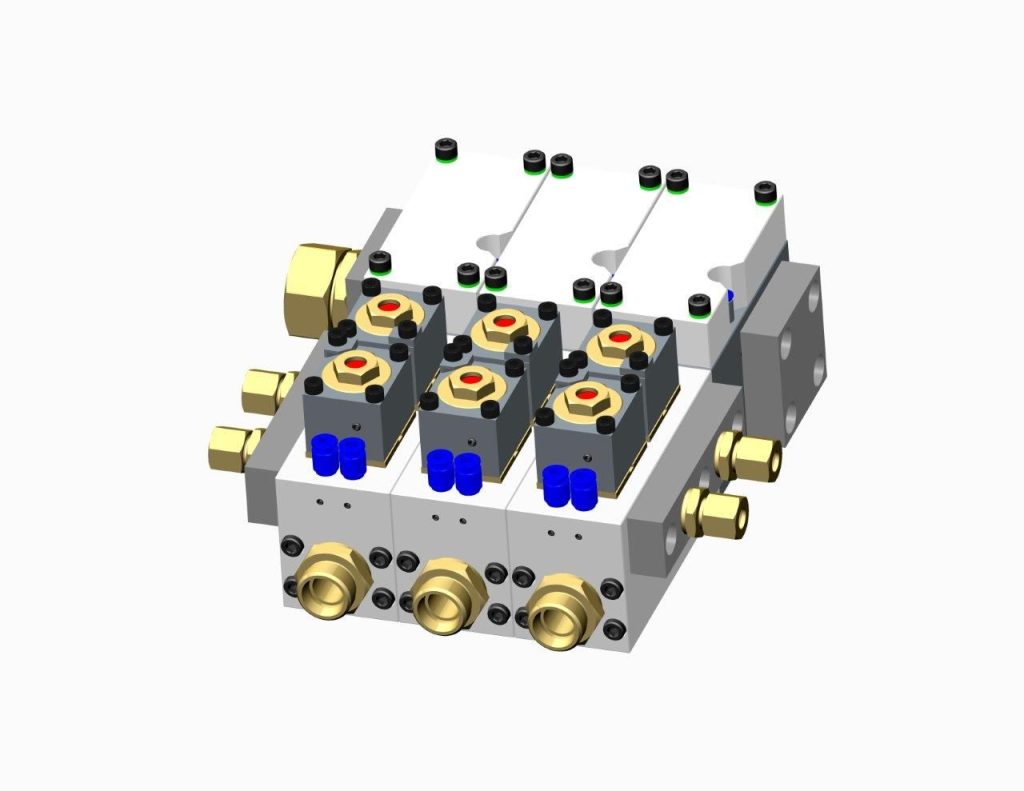

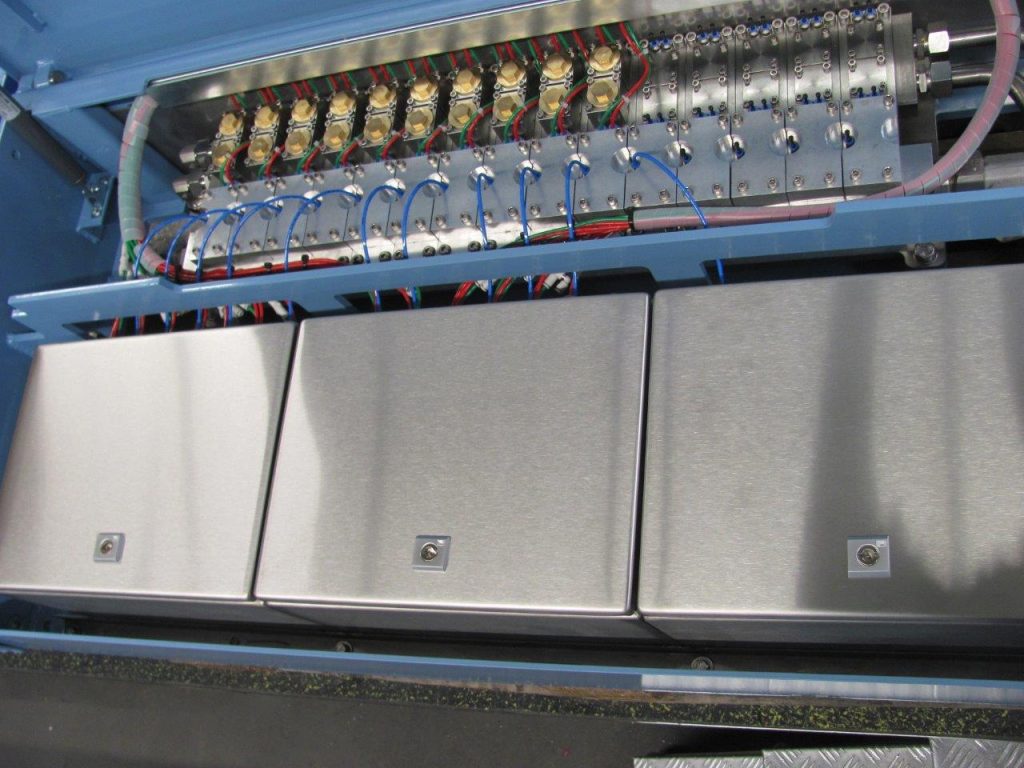

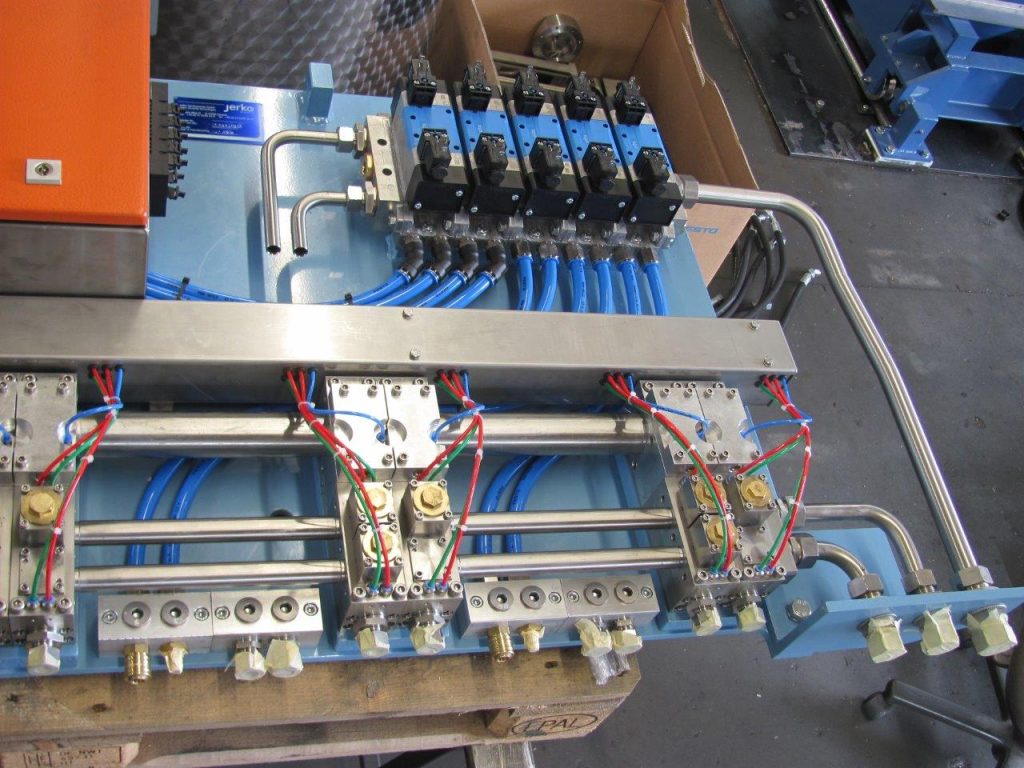

🔹 Discuss how the right spray system impacts die lifetime, productivity, and cost efficiency.

🔹 Explore practical solutions that have already proven themselves in production worldwide.

For decision-makers across the forging supply chain, IFC is more than an exhibition – it’s a platform to shape the future of our industry.

📍 Let’s meet in Frankfurt – Booth 33 & 34.

We look forward to insightful discussions with you.

Check out IFC homepage for more information:

https://ifc2025.com/