One spray head for all applications

What you can expect

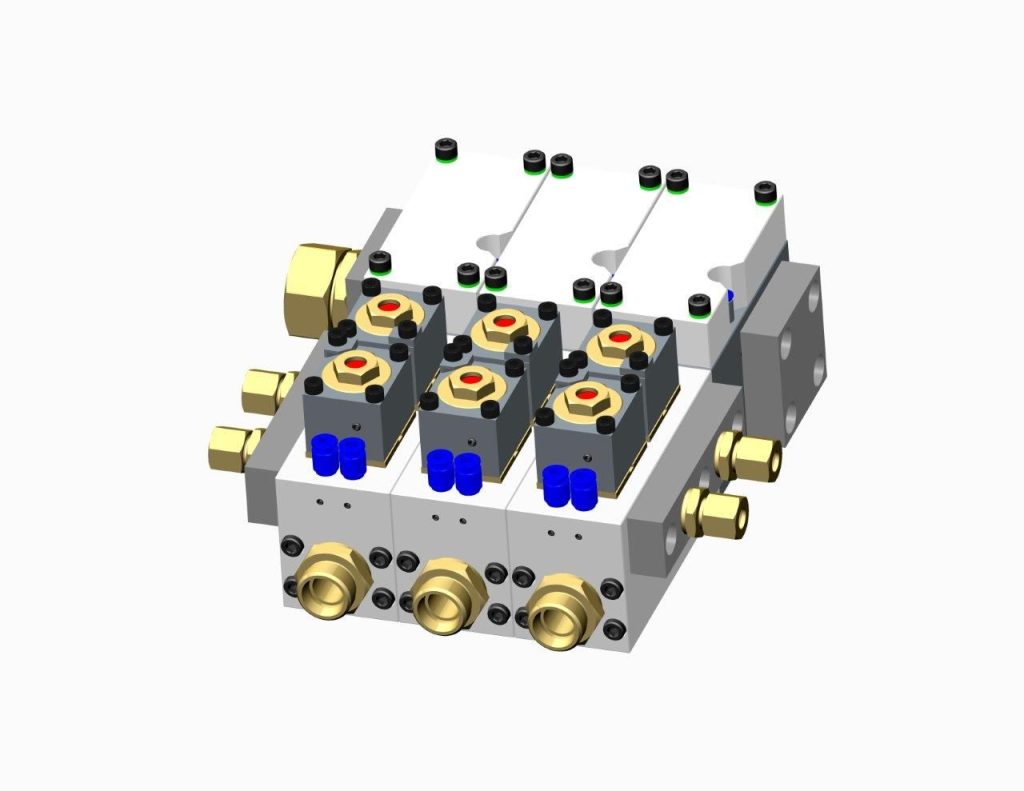

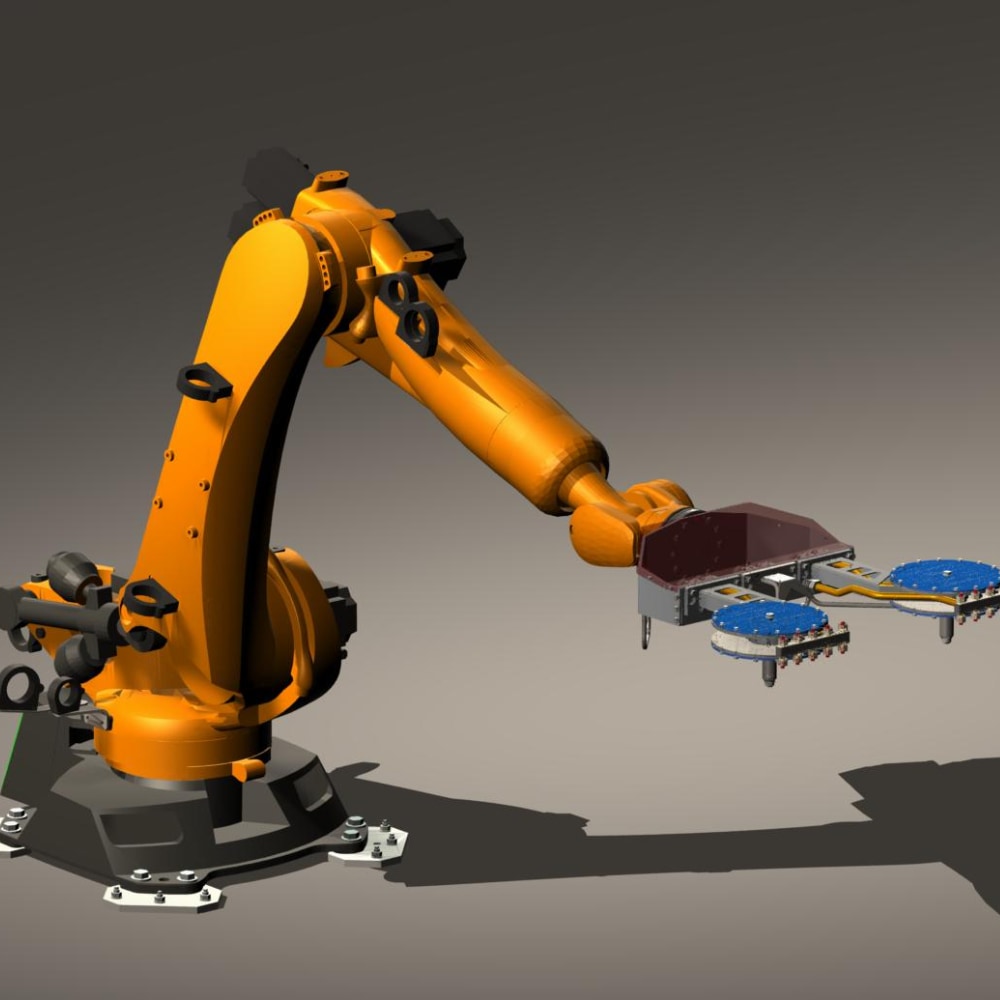

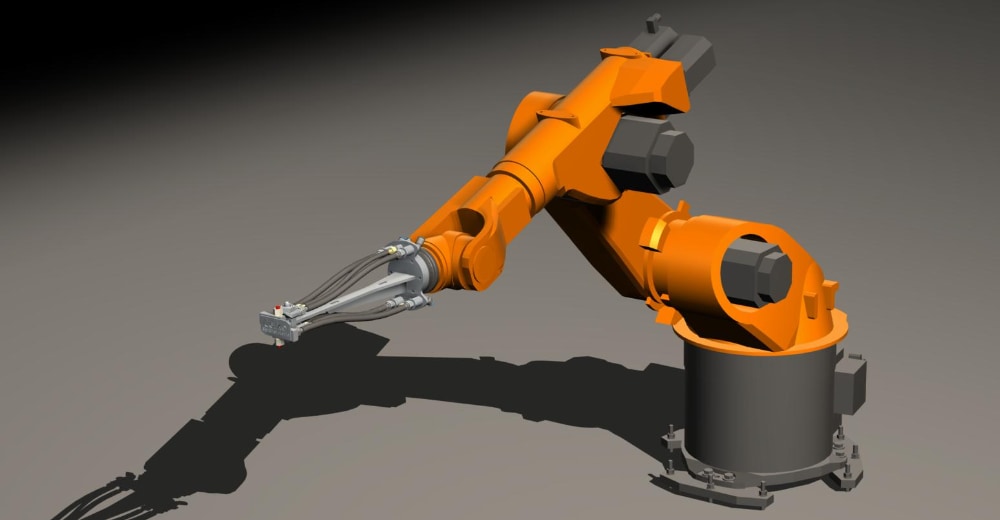

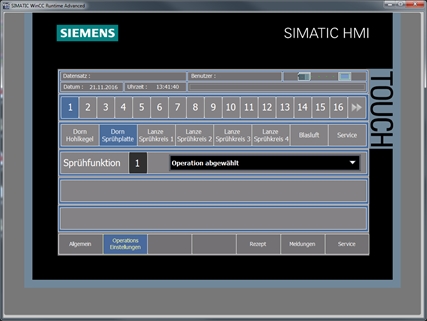

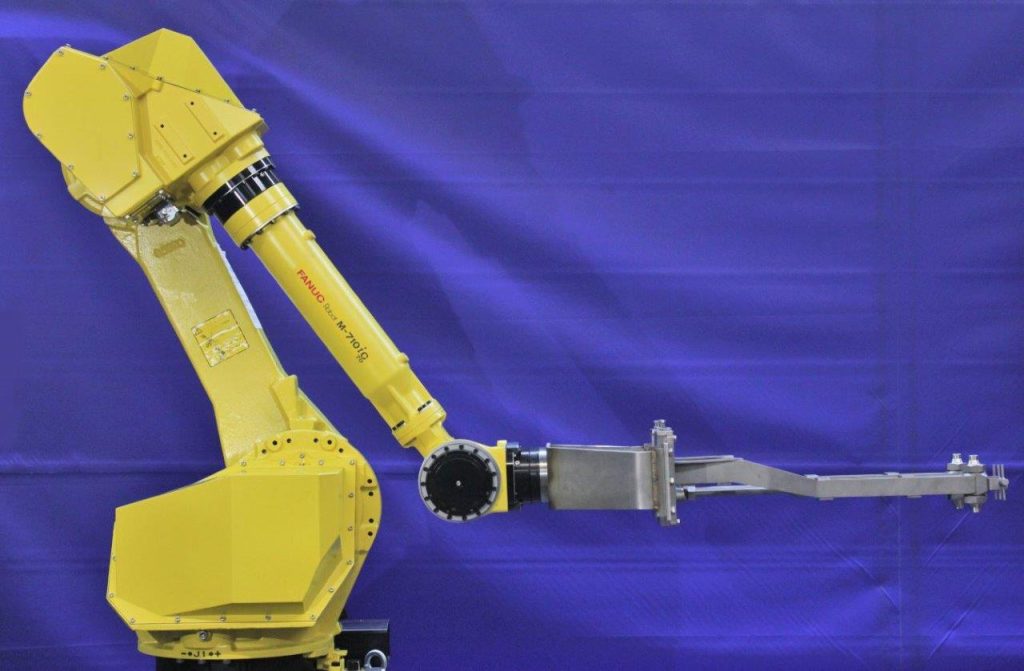

The revolution in spraying technology! The patent registered single nozzle spray head combines the best of both worlds. Robust, simple and highly flexible in application. Each nozzle spray head can be controlled individually or in groups. Every possible contour can be sprayed – without set-up times.

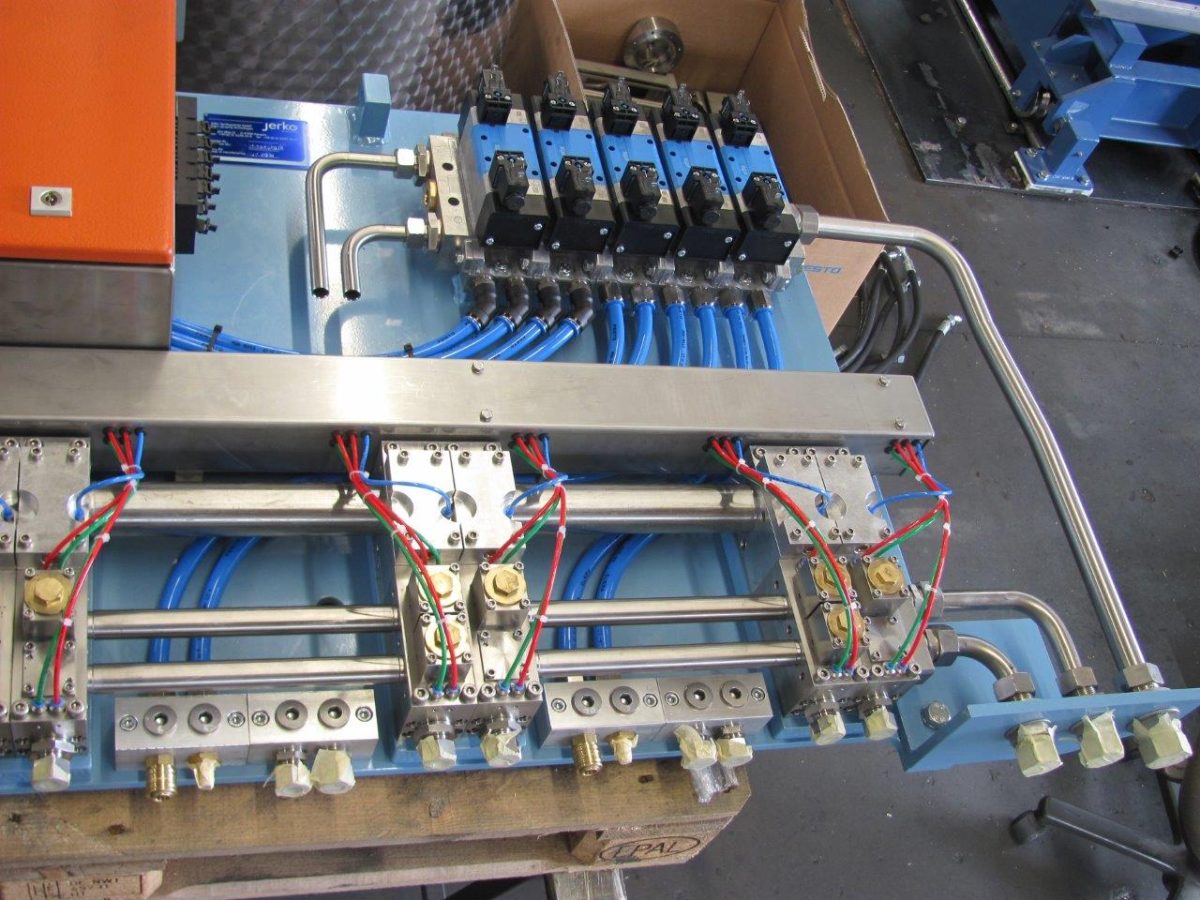

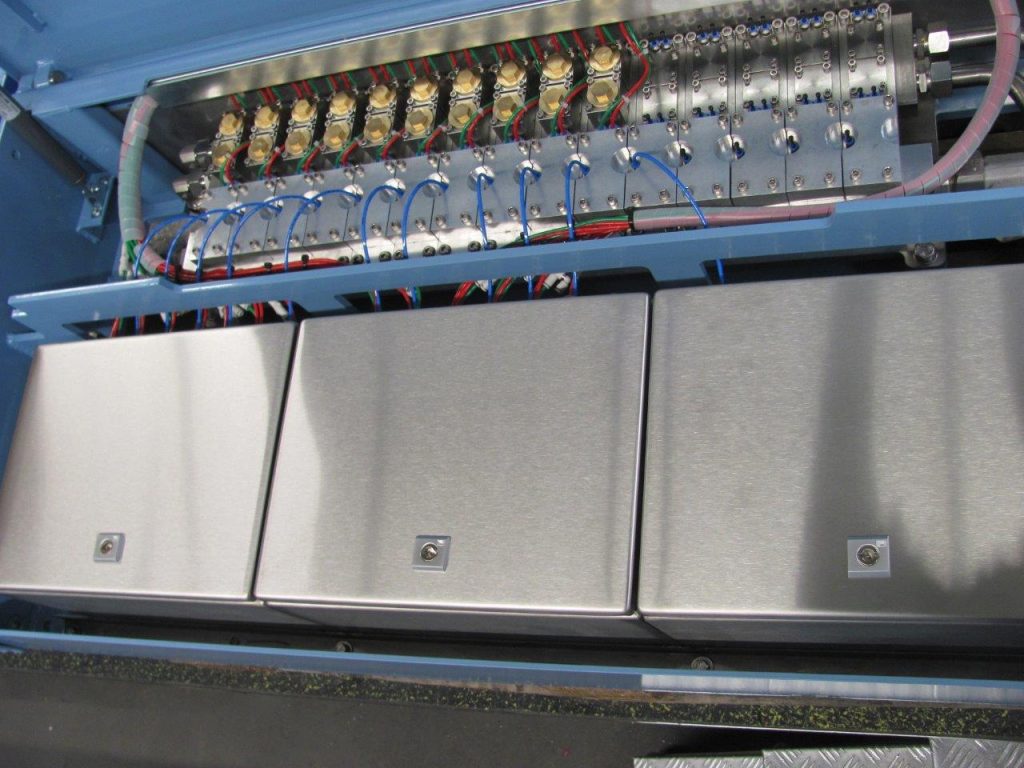

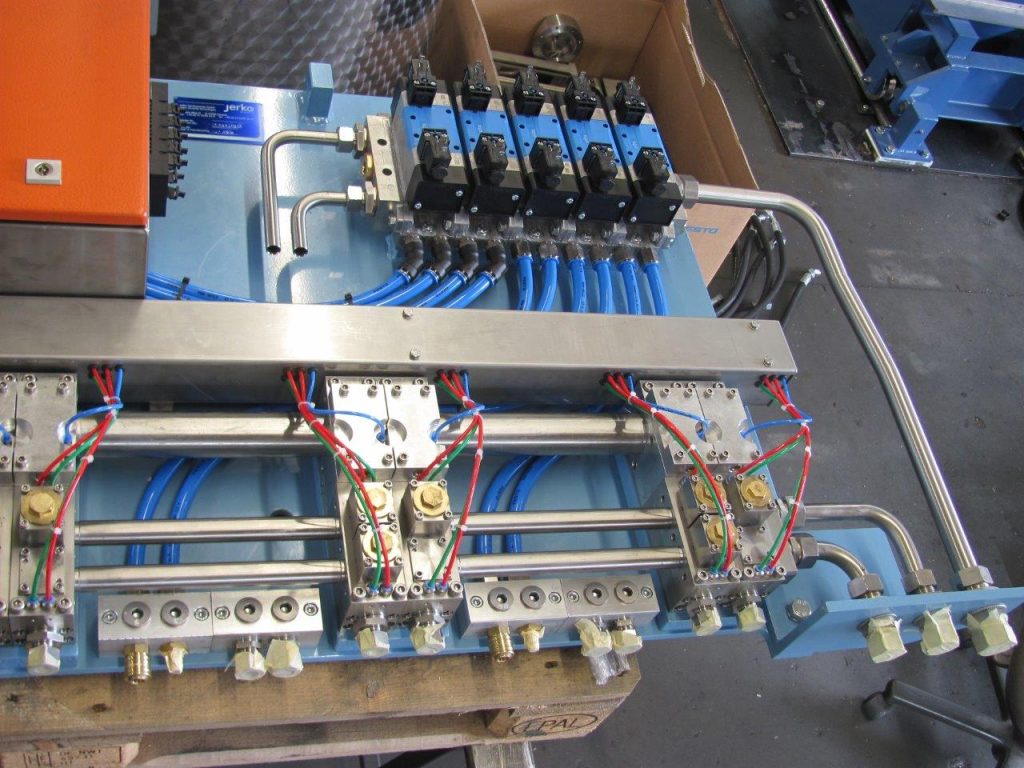

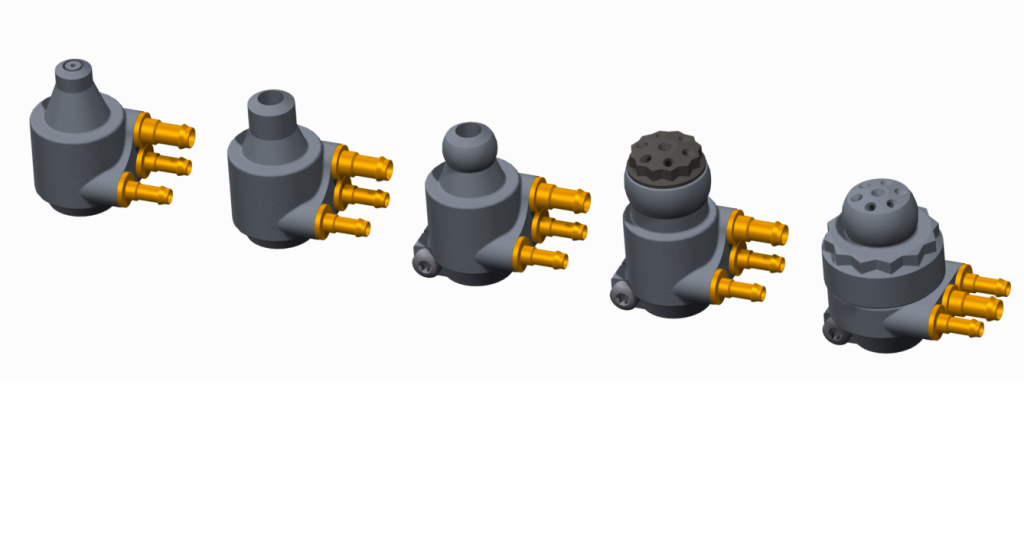

How does it work? The nozzle plate is made by simple stainless steel parts. The nozzles are then individually fixed on a matrix – that’ s it! The control can be done in groups or individually – at any time! Every single spray jet can be individually changed by exchangeable nozzle heads.

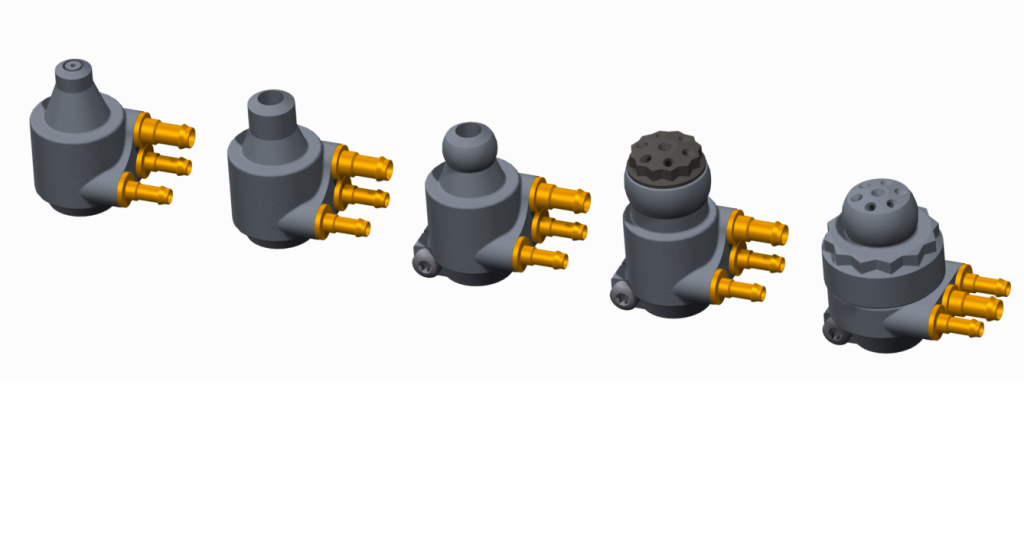

What is the cost? Thanks to the use of the most modern materials and additive manufacturing processes, the nozzles cost only a very low percentage compared to conventionally machined nozzles.

Advantages at a glance

patent registered modular spraying system

the most flexible system on the market

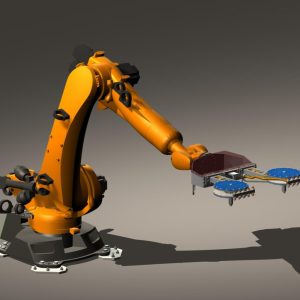

Precisely contoured spray head for complicated geometries

cheap due to 3D- print

Spray circles can be extended at any time

no moving parts in the spray nozzle

designed and built according to MRL 2006/42 EG

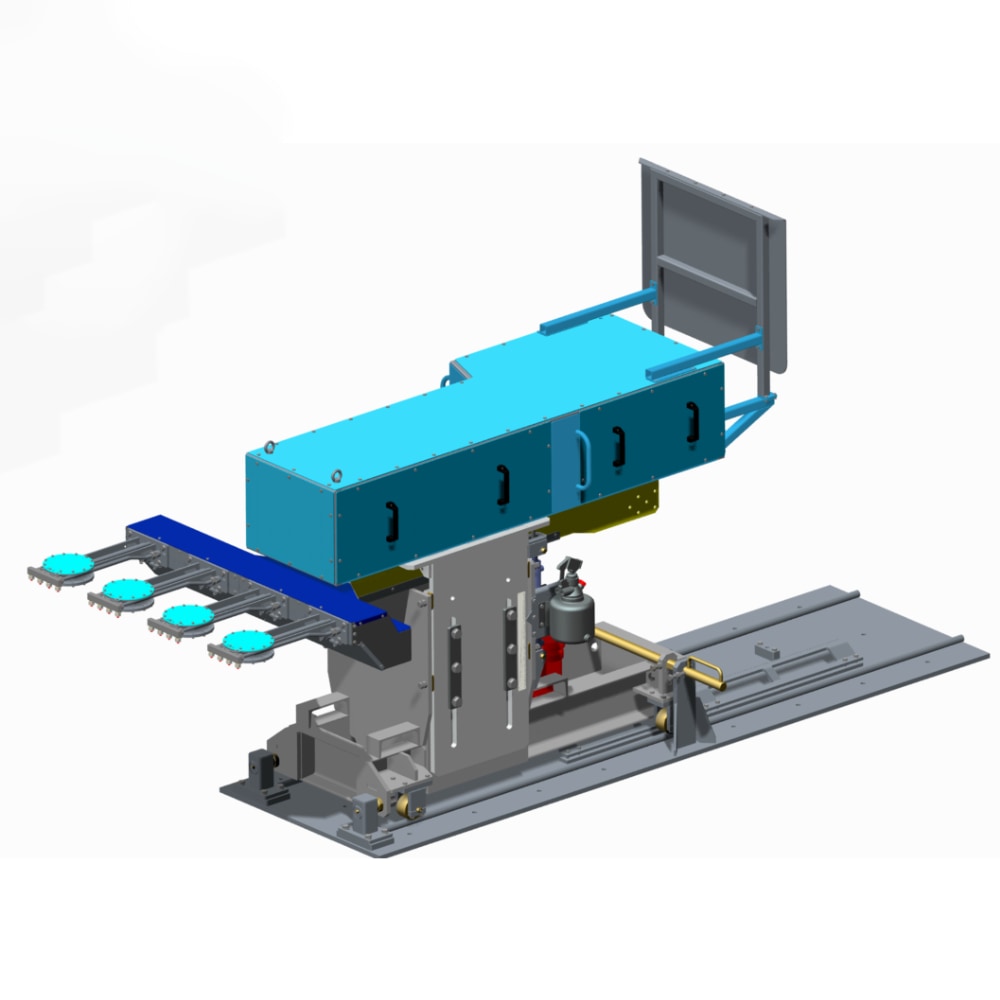

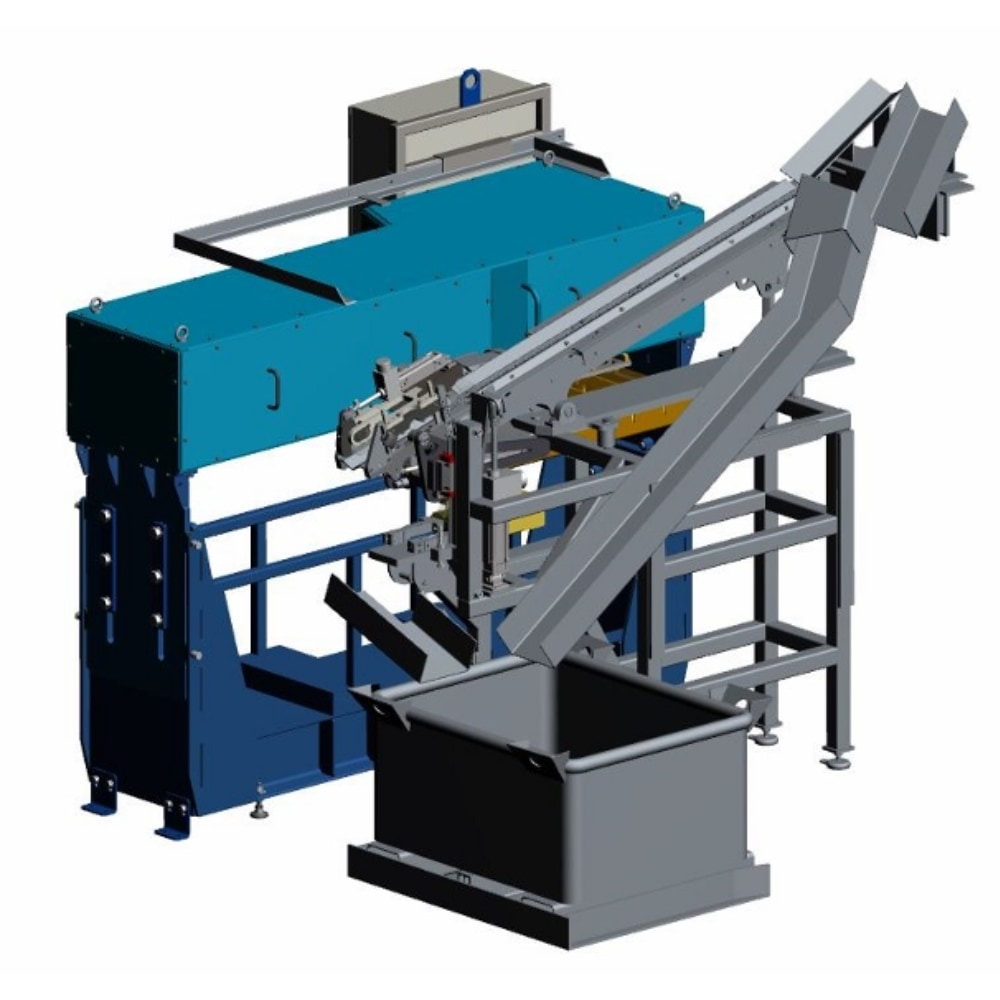

Sizes

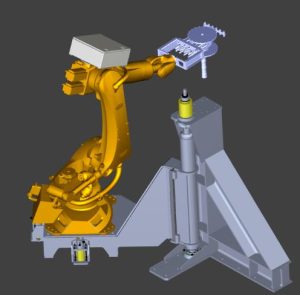

You decide how large the spray head should be. The carrier plate for the individual nozzles is adapted to the contour and designed as a simple welded part.

The type and number of nozzles are freely selectable. Our registered patent system allows the nozzles to be simply plugged on and the spray patterns to be changed.

The nozzles can be controlled individually or in groups.

And here is the next revolution: It can be changed at any time!

You know the situation: The spray head is produced and you have to adjust the spraying circles afterwards because of a small change of the contour? With the Jerko- System you are able to add, combine or extend spray circuits in a completely flexible way. Without cost-intensive changes to the spray head or a expensive new production.

The advantages of this system are clear.

Do not hesitate and contact us. Our experts are looking forward to a new challenge!