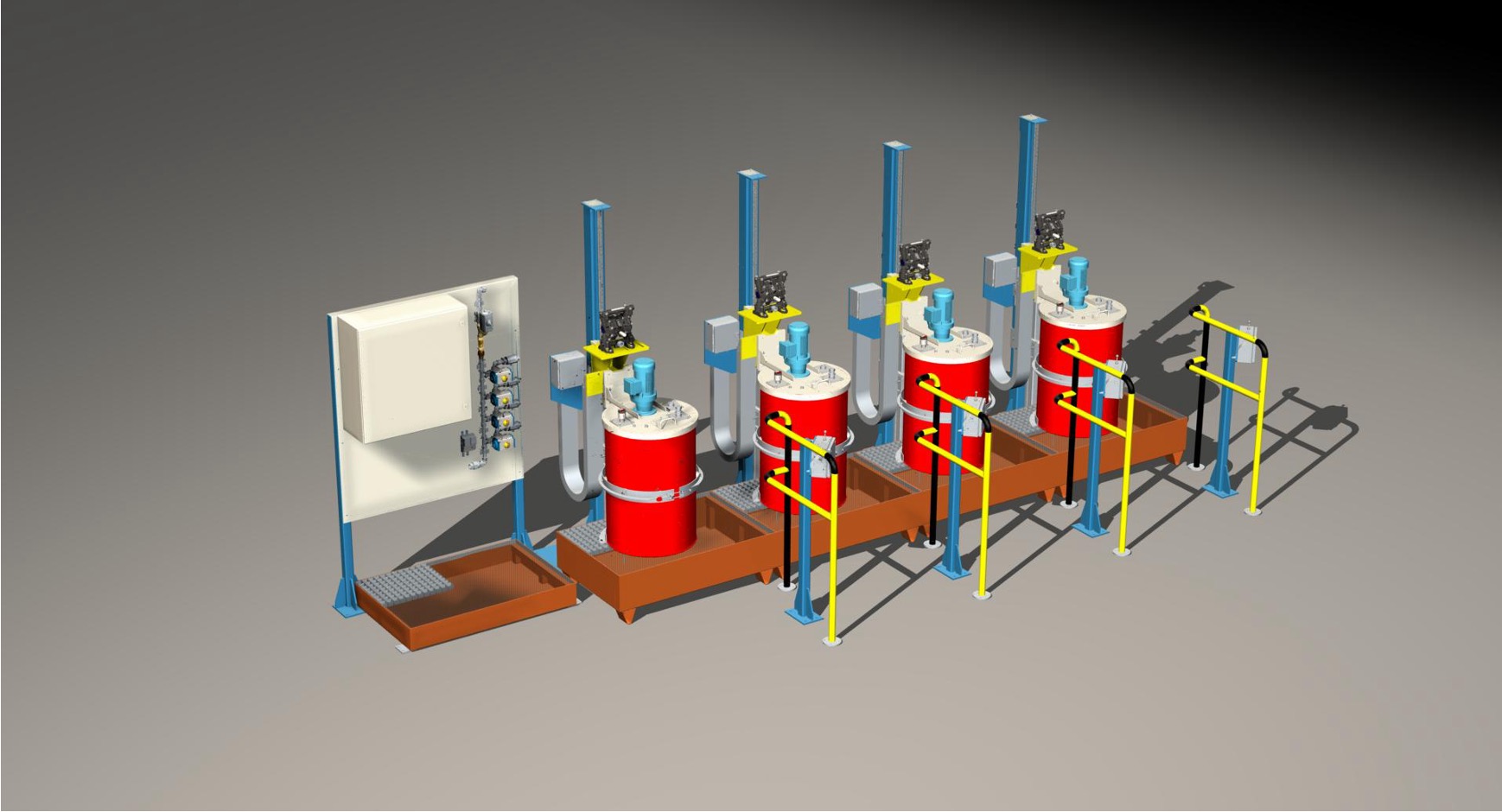

Simple, Modular, Safe

Jerko’s Barrel and IBC stations are ideal for stirring a wide range of lubricants such as dispersions, suspensions, or emulsions prior to their application. This ensures that the concentration remains consistent during dosing.

Thanks to the modular design, multiple stations can be combined into a central supply unit – allowing the simultaneous dosing of different lubricants.

The robust and well-engineered construction guarantees trouble-free operation and ensures consistently high lubricant quality.

Various geometries of the stirring elements enable a choice between gentle and intensive mixing, depending on the requirements.

Manual or automatic lifting/lowering

Modular design – ideal for central dosing stations with multiple media

Safe!

Developed and certified in accordance with Machinery Directive 2006/42/EC

Barrel Station

Dimensions (L × W × H): 900 × 900 × 2200 mm

Container: 200 litres, open-head drum

Viscosity (at 20 °C): up to 5,000 mPas

Features:

Catch pan

Level sensor

Diaphragm pump

IBC Station

Dimensions (L × W × H): 1400 × 1400 × 2400 mm

Container: IBC, 1000 litres

Viscosity (at 20 °C): up to 5,000 mPas

Features:

Catch pan

Level sensor

Diaphragm pump

Stirrer: Fixed or adjustable speed

Stirring elements: Propeller, cup, and other variants

Various pump types available

THE NO.1 SPRAY TECHNOLOGY FOR FORGING

Jerko is the No. 1 in high-performance spray and coating systems for forging industry.

Our mission: Maximize uptime. Minimize costs.

Powered by PBMSys