Maximum Die Lifetime. Minimum Downtime.

Efficiency boost for warm forging.

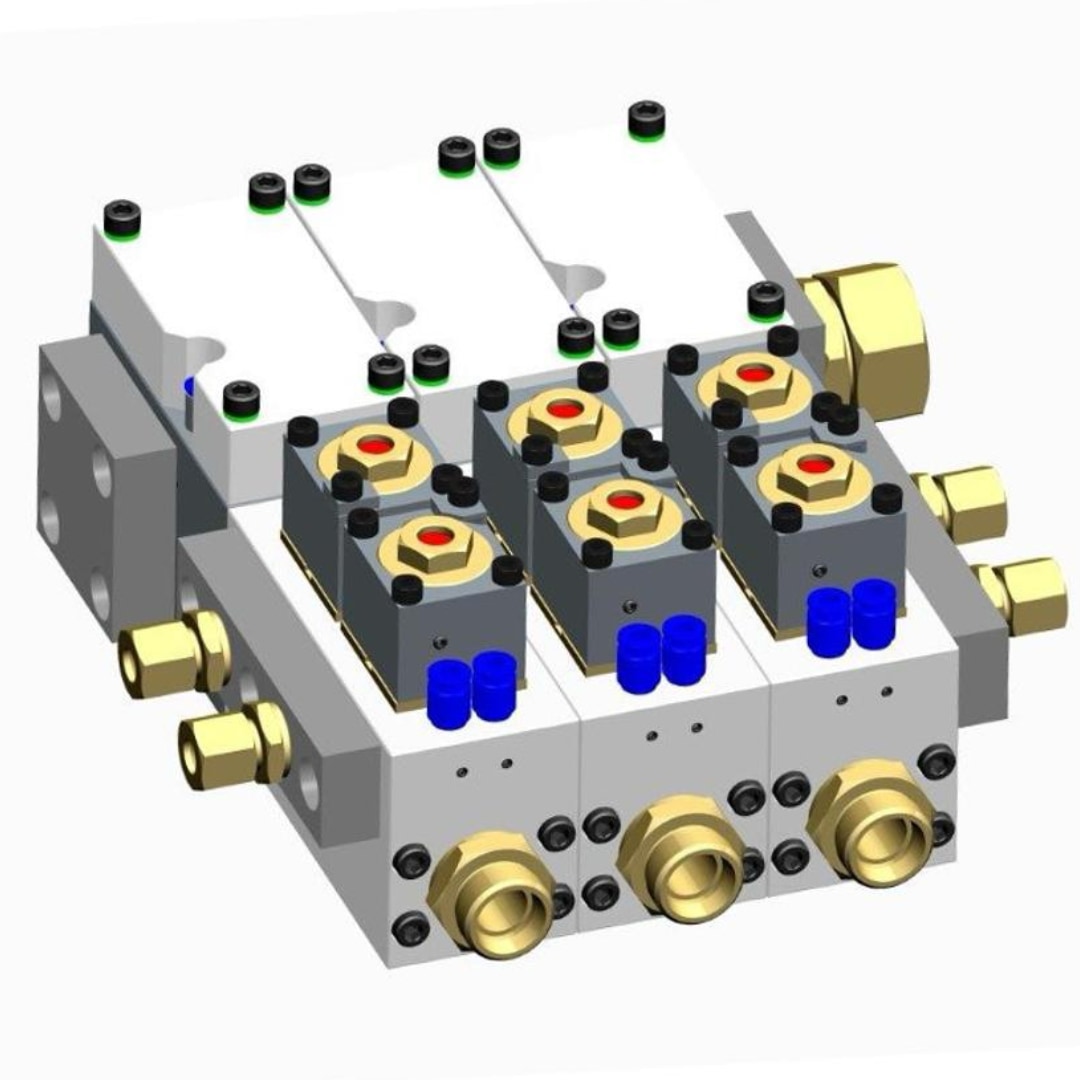

If you’re serious about efficiency in warm forging, there’s no getting around the Jerko Spray Mixing Block.

Our technology is purpose-built for extreme conditions: high temperatures, ultra-short cycle times, and maximum tool wear resistance.

That’s where the Spray Mixing Block shows its full strength.

The fastest forging lines are already running with our system – delivering measurable results for our customers:

Significantly longer tool lifetimes

Fewer downtimes due to maintenance

Higher machine availability

In CV-joint production for warm forging, our system is state of the art.

Those who still rely on conventional solutions today are losing money daily.

We’ll help you take your line to the next level – with zero risk and a measurable ROI.

100% dead-space-free – no clogging, no build-up

Sandwich construction for up to 20 spray points side by side

Extremely short switching times

Continuous adjustment of flow rate

Simple installation and repair

SMB1 – 1421 & SMB2 – 1421

Nominal diameter: Ø 2.5 mm

Number of media: 1 & 2

Viscosity at 20 °C: 400 mPas

Reaction time: < 10 ms

Temperature range: +5 °C – 95 °C

SMB1 — 1422 & SMB2 — 1422

Nominal diameter: Ø 4.0 mm

Number of media: 1 & 2

Viscosity at 20 °C: 400 mPas

Reaction time: < 10 ms

Temperature range: +5 °C – 95 °C

NBR / Viton / EPDM seals

Fixed orifices for defined flow rates

Adjustable orifices for fine-tuning

Precision adjustment with locking function

Jerko is the No. 1 in high-performance spray and coating systems for forging industry.

Our mission: Maximize uptime. Minimize costs.

Powered by PBMSys