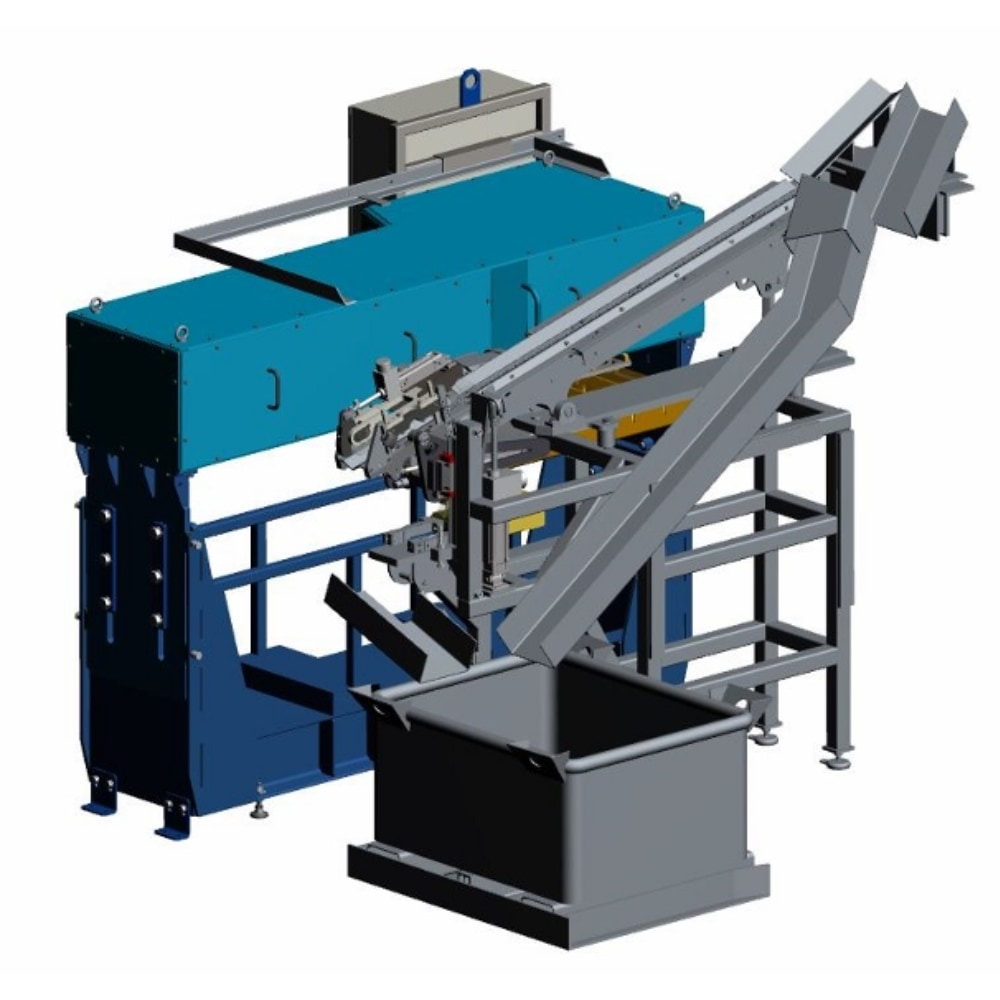

Separation And Feeding Of Forged Parts

Vision & Teamwork

Profit from our know-how

SEPARATING – SORTING – FEEDING – SPRAYING

The task: For a retrofit on a hot forging line a part separation and a spray system with low space requirements must be integrated. The aim is to reduce the cycle time, multiply the product range and increase productivity. No easy task!

The solution: A combination of our high-speed manipulators with special grippers and a newly developed part separation system. Together with our customer and our innovative employees, we have developed a new way of part separation. With this system parts from Ø 30 mm – 99 mm and a length of 36 mm – 180 mm can be fed safely. The combination of spraying and gripping enables an extremely space-saving machine.

Parameters at a glance

- Ø 30mm – 99 mm

- Part length 36 mm – 180 mm

- Diameter-length ratio from 1.15

- Safe sorting of the different temperatures

- Runtime monitoring for forged parts

- Designed and built according to machinery directive 2006/42 EG

We would like to thank our customer for the trust they have placed in us